Efficient site operations rely on the right tools and strategies. Modern construction and industrial projects face constant pressure to reduce downtime and increase productivity. Integrating advanced equipment management techniques ensures that machinery is used effectively and safely. By focusing on the right technology and processes, sites can achieve smoother workflows and improved outcomes.

Maximizing Efficiency With Plant Machinery Hire

Plant machinery hire refers to renting heavy machinery such as excavators, loaders, and cranes instead of purchasing them outright. This approach offers flexibility, reduces capital expenditure, and ensures access to the latest equipment. Companies can scale operations up or down based on project demands. With proper planning, plant machinery hire allows sites to maintain productivity without tying up valuable resources, making operations more streamlined and cost-effective.

Enhancing Site Performance With Pump-Off Control

Pump-off control is a system used in fluid management to prevent over-pumping and equipment strain. It monitors flow and automatically adjusts operations, protecting both machinery and personnel. Implementing pump-off control minimizes waste and avoids costly maintenance. For sites managing fluids like water, fuel, or slurry, this technology ensures continuous operations while reducing downtime. Efficient pump-off control directly contributes to safer and more reliable site workflows.

Reducing Maintenance Risks Through Equipment Monitoring

Modern sites increasingly rely on monitoring systems to track machinery health. Sensors can detect vibrations, temperature changes, and wear patterns, signaling maintenance needs before failures occur. By integrating real-time monitoring, operations teams can plan repairs, prevent breakdowns, and extend equipment life. This proactive approach reduces unexpected stoppages and ensures that both hired machinery and permanent assets perform optimally.

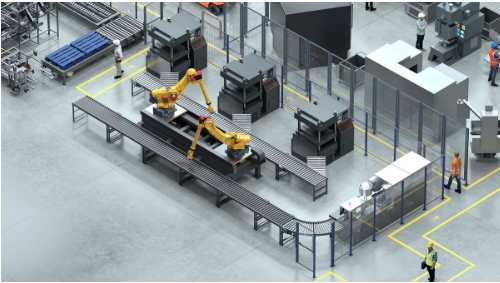

Streamlining Operations With Integrated Plant Machinery Hire

Combining plant machinery hire with advanced management tools creates a seamless operational framework. Rental equipment can be tracked, scheduled, and maintained using centralized software systems. This integration reduces idle time and ensures machines are available when needed. By pairing plant machinery hire with structured management processes, sites can achieve a higher level of efficiency, minimize delays, and optimize workforce allocation.

Optimizing Fluid Systems Through Advanced Pump-Off Control

Beyond basic flow regulation, modern pump-off control systems use predictive analytics to adapt to varying site conditions. These systems analyze pressure and output trends, adjusting operations to prevent equipment fatigue. Implementing advanced pump-off control reduces energy consumption and extends the lifespan of pumps. Sites that adopt these systems can maintain steady operations while lowering operational costs and improving overall fluid management.

Improving Safety Standards With Modern Equipment Management

Safety is a critical factor in every operation. Modern equipment management incorporates automated alerts, safety interlocks, and compliance tracking. These tools prevent accidents caused by overuse, operator error, or equipment malfunction. Integrating safety protocols with plant machinery hire and pump-off control ensures that both temporary and permanent assets are used responsibly. A focus on safety not only protects personnel but also safeguards project timelines and budgets.

Conclusion

Optimizing site operations demands a combination of the right equipment and intelligent management practices. Plant machinery hire provides flexibility and cost efficiency, while pump-off control ensures reliable fluid handling and machinery protection. By embracing modern monitoring, integration, and safety strategies, sites can reduce downtime, enhance productivity, and achieve better results. Investing in these technologies allows operations to run smoothly, making every project more efficient and profitable.